Syringe pump software for multi pump control

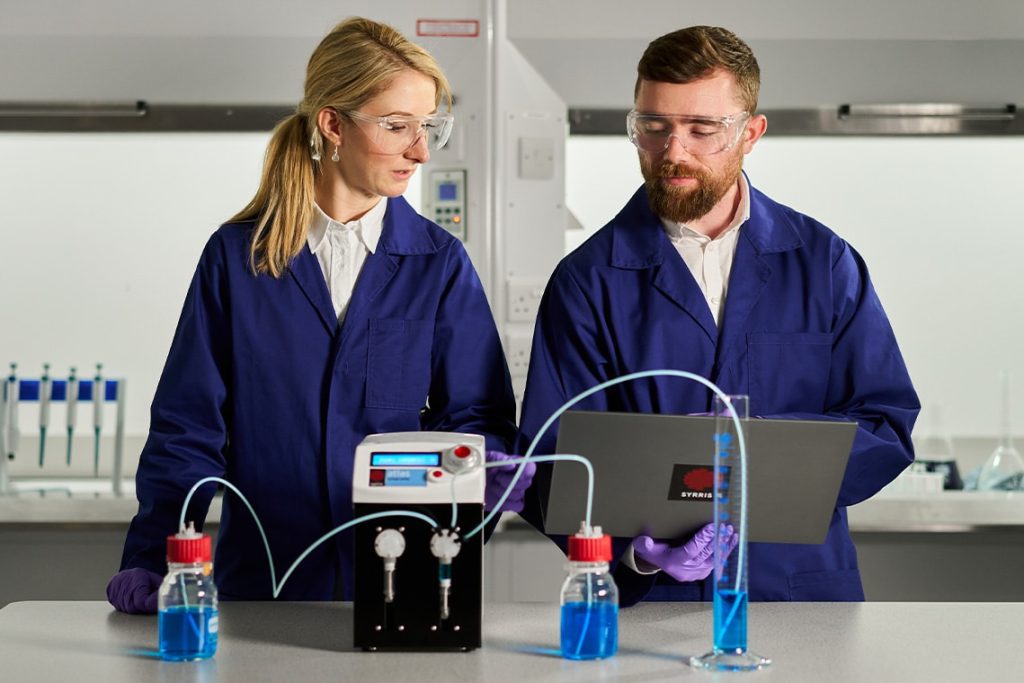

Modern laboratories demand precision, reproducibility, and efficiency. Yet manual syringe pump operation remains one of the most time-consuming and error-prone tasks in fluid handling. From synchronizing multiple syringe pumps to managing flow rates and recording data, manual control limits what researchers can achieve.

Syringe pump software — also known as syringe pump control software or programmable syringe pump software — transforms this process. It gives scientists, engineers, and technicians a single platform to control pumps, automate workflows, and log data with confidence.

Whether you’re running a single dosing experiment or coordinating an array of syringe pumps, laboratory syringe pump software delivers the precision, flexibility, and automation modern research requires.

The challenges of traditional syringe pump control

Manual pump control consumes valuable time and introduces variability. Adjusting flow rate by hand, calibrating syringe sizes, and monitoring delivery over long experiments leave room for drift and inconsistency.

Synchronizing multiple syringe pumps manually is even harder — especially when coordinating complex pump programs or multi-channel setups. Researchers also face challenges exporting reliable data or maintaining audit trails for compliance.

Without pump software, these issues can slow down discovery, compromise reproducibility, and limit lab productivity.

Introducing syringe pump software: automate, control, and simplify

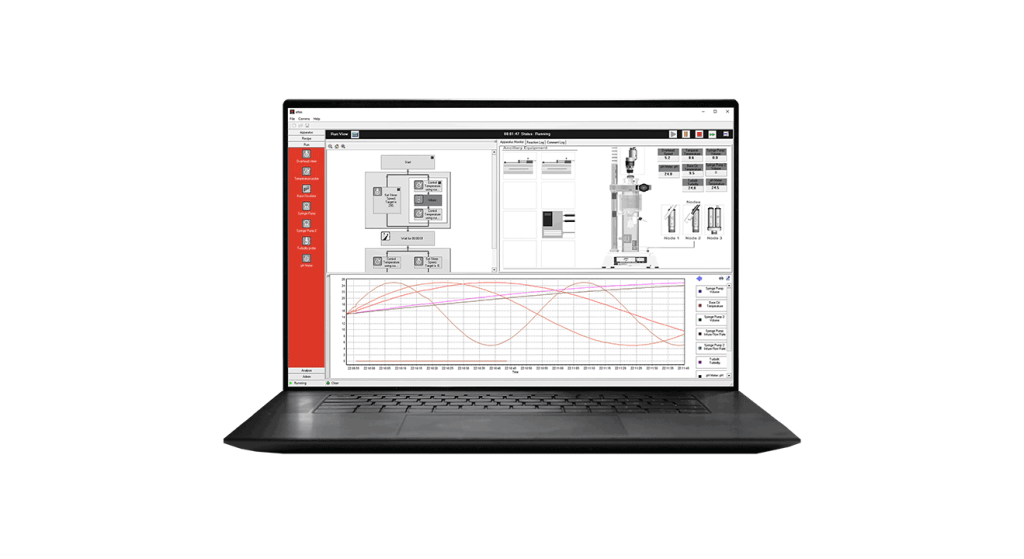

Syringe pump automation software streamlines every aspect of pump programming and operation. With intuitive interfaces, flexible control, and real-time monitoring, it transforms how you control pumps in your lab.

- Automate fluid delivery: Build dosing profiles with ramps, steps, and pauses for consistent, repeatable runs.

- Control multiple pumps: Manage a network of syringe pumps simultaneously or sequentially from a single PC.

- Simplify setup: Automatically detect COM ports, configure baud rates, and accurate flow control.

- Enhance precision: Maintain constant or variable flow rates with programmable control.

- Monitor and log: Capture live data, export to CSV, and integrate with your existing lab automation systems to automatically monitor all pump parameters.

With reliable pump software, researchers can control pumps remotely, queue up pump programs, and create sophisticated profiles that improve repeatability and save time.

Key features and benefits of syringe pump software

- Complete pump control

From manual adjustments to fully automated operation, pump control software gives you total command. Control individual or grouped pumps locally or via remote pump interfaces and monitor flow parameters in real time - Advanced pump programming

Create and store reusable pump programs that define flow rate profiles for different applications. With easy drag-and-drop editors or scripting options, you can customize ramps, loops, or waveform-based dosing. - Multi-pump synchronization

Run multiple syringe pumps in perfect sync. Advanced queue scheduling and grouping ensure accurate reagent delivery and timing for even the most complex experiments. - Real-time monitoring and data logging

View live flow rate data, syringe position, and pump status on your screen. Record every event automatically, then export for further review. - Seamless connectivity

Most laboratory syringe pump software supports RS-232 and USB connections, often using USB-to-RS232 adapters to create virtual COM ports. Clear serial settings (baud rate, parity, stop bits) simplify setup and detection. - Automation and integration

Certain software allows syringe pump integration with LabVIEW, MATLAB, or Python through APIs or simple serial commands. Create custom automation scripts that coordinate pump programming with other laboratory instruments for a fully connected workflow. Asia External Control offers control and automation of Asia Syringe Pumps using third-party OPC UA Software.

Syrris syringe pump software vs. the competition

When evaluating syringe pump control software, consider compatibility, usability, and automation capability.

| Typical feature | Typical legacy software | Syrris syringe pump control software |

| Multi-Pump Control | Limited | Full simultaneous/group control |

| Flow Rate Accuracy | Manual adjustment | Automated precision |

| Integration Options | Basic | Includes: API, LabVIEW, MATLAB, Python, OPC UA |

| Data Logging | Minimal | Full CSV export |

| User Interface | Complex | Intuitive, visual editors |

| Compatibility | Single brand | Broad, multi-model support |

Legacy software packages from brands like Harvard Apparatus or KD Scientific often provide basic control but can lack modern automation and flexibility. Syrris champions versatile, future-ready solutions designed for seamless pump control, powerful integration, and real-world lab productivity.

Compliance and Security

For regulated laboratories, software validation and data integrity are non-negotiable.

- Security: Role-based access, local-only modes, and check-sum-verified installers keep systems protected.

- Traceability: Automatic logs capture every run parameter for easy retrieval during audits.

With robust compliance support, your pump programming workflows remain secure, transparent, and reproducible.

Get started with Syrris

Automating syringe pumps saves time, increases precision, and unlocks new experimental possibilities. To explore laboratory automation further, Syrris offers:

- Atlas PC Software – designed for batch chemistry automation and data capture.

- Asia Manager PC Software – built for flow chemistry and continuous processing.

- Asia External Control control and automation of Asia Syringe Pumps using third-party OPC UA Software.

These platforms demonstrate how intuitive interfaces, reliable pump control, and powerful data logging can transform laboratory workflows.

Contact us

Ready to elevate your lab’s automation? Contact Syrris today to discuss syringe pump and multi-pump software solutions, compatibility guidance, and demo options tailored to your research.

Syringe pump software terminology

- RS-232 (serial): A legacy serial communication standard used by many syringe and peristaltic pumps, typically via a DB9 connector.

- USB / USB-RS232 adapter: Allows PCs to connect to pumps via a virtual COM port (VCP).

- COM port: The numbered serial interface (e.g., COM3) through which pump software communicates with each device.

- Baud rate: The speed of serial communication, measured in bits per second (bps). Must match the pump’s settings.

- Flow rate: The volume delivered per unit time (e.g., µL/min or mL/min).

- Firmware: The internal software running on a syringe or peristaltic pump; determines feature compatibility.

- Peristaltic pump: Peristaltic pumps dispense fluid using a rotating roller mechanism to create alternating compression and relaxation of a flexible tube.

- Profile / Queue: A programmed sequence of pump programs, steps, or ramps that define a pump’s operation over time.

- Syringe pump: Syringe pumps, or syringe drivers, are devices that accurately control the delivery of a fluid from a syringe typically by automation of the plunger.

- Syringe size calibration: The process of matching the syringe volume and dimensions to ensure accurate flow rate calculations.

Syringe pump software frequently asked questions

Which pump models are compatible?

Compatibility varies by software, but most platforms support a wide range of syringe pumps via RS-232 or USB. Always confirm firmware versions for best results.

Can I control multiple pumps at once?

Yes. Most programmable syringe pump software enables simultaneous or sequential multi-pump control. You can group pumps and schedule runs for parallel or staggered operation.

Can I create and schedule pump programs?

Absolutely. You can design pump programs with ramps, steps, pauses, and loops — ideal for flow chemistry, microfluidics, or reagent dosing applications.

How far away can my remote pump setup be?

Distance depends on connection type. RS-232 cables typically operate reliably up to 15 m, while USB setups may require powered extenders for longer runs.

Why should I choose a syringe pump over a peristaltic pump?

Both syringe pumps and peristaltic pumps have their place, depending on the application. Syringe pumps generally offer higher precision and accuracy, high chemical compatibility, require no calibration, and offer pulse free flow. Peristaltic pumps can pump light slurries and suspensions, however, have limited flow rates, high pulsation, poor chemical compatibility, and require calibration.