Automated Syringe Pump Buyer’s Guide: Types, Specs & Selection

What is an automated syringe pump?

An automated syringe pump is a precision fluid handling instrument designed to deliver accurate and controlled volumes of liquid. It operates by mechanically controlling the movement of a syringe plunger.

Key components: The core mechanism consists of a motor (often a stepper motor for precise control), a drive mechanism, a syringe holder, and a control software or interface. The motor drives the plunger, pushing or pulling liquid from the syringe to achieve tasks like infusion (delivery) or withdrawal (aspiration).

Advantages of automated syringe pumps over manual methods: Automated single syringe or dual syringe pumps offer significant advantages over manual dosing, primarily in precision, control, and automation. They eliminate the variability associated with manual additions, ensuring reproducible high precision results critical for complex chemical transformations and research. They allow for automated dosing routines and integration with other lab equipment for walk-away chemistry. This precision is a key factor, as the Atlas Syringe Pump, for instance, offers a typical precision of 0.06% CV.

Types of syringe pumps

Automated syringe pumps are categorized based on their mechanism and intended use, offering different functionalities.

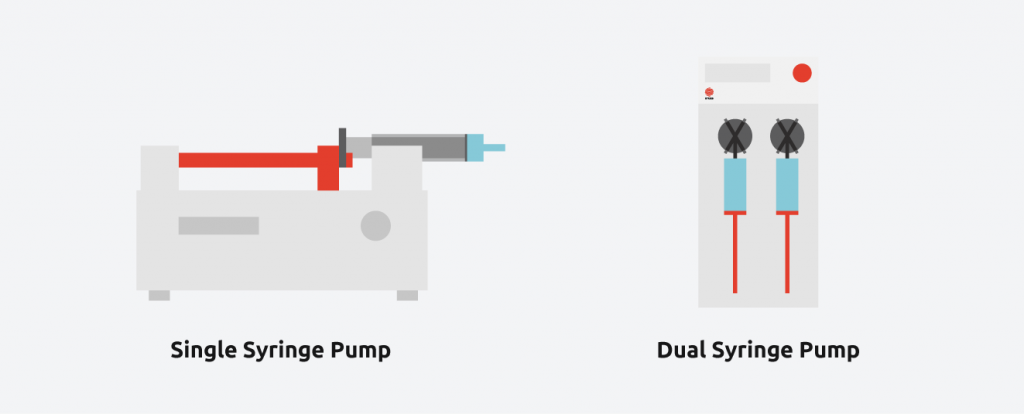

- Single syringe pumps: These models feature one syringe and are primarily used for infusion (dosing) or withdrawal (aspirating/sampling). Single syringe pumps are suitable for applications where continuous flow or two-reagent dosing isn’t necessary.

- Dual syringe pumps (dual dosing mode): Equipped with two independent syringe channels, dual syringe pumps allow for simultaneous and independent dosing of two different reagents. This mode is excellent for complex reaction setups.

- Continuous syringe pumps (continuous flow mode): This type utilizes the dual syringe channels to work together, providing a single, stable, and continuous flow. While one syringe is dispensing or metering, the other is refilling, enabling seamless, pulseless flow crucial for applications including flow chemistry and microfluidics. These can sometimes be referred to as precision infusion pumps.

- Programmable syringe pumps: These syringe pumps, also referred to as computer-controlled pumps, pc-controlled syringe pumps, or digital syringe pumps, can execute complex, automated dosing profiles (recipes) and integrate external inputs. This includes advanced modes like pH control and temperature-dependent dosing, which are critical for walk-away experiments.

- Laboratory syringe pumps: Designed for research and development applications, laboratory syringe pumps offer high precision, chemical compatibility (e.g., glass, PTFE, PCFE wetted parts), and the versatility required for various experiments. The Syrris Atlas Syringe Pump and Atlas Syringe Pump XL are examples of specialized laboratory syringe pumps, with the XL version offering significantly higher flow rates for larger processes.

Applications of automated syringe pumps

Automated syringe pumps are integral tools across diverse fields due to their superior accuracy and control.

- Laboratory use: research and development, solution chemistry: They are widely used for high precision reagent addition, kinetic studies, and reaction optimization where accurate volume or flow rate is critical for reproducible results. Specialized laboratory syringe pumps automation capabilities allow for “walk-away” chemistry, freeing up researcher time.

- Microfluidics: Syringe pumps are the preferred fluidic control method for microfluidics, enabling the precise handling of minute fluid volumes. The low-pulsation flow delivered by high-quality models is essential for stable droplet formation and flow focusing.

- Flow chemistry: In continuous flow synthesis, single syringe or dual syringe pumps are a critical component, ensuring precise molar ratios and residence times by accurately controlling the flow rate. Continuous dosing modes using dual syringe pumps are vital for stable, pulseless flow that defines the flow chemistry reaction environment.

- Thin film deposition: They enable the controlled deposition of precursor solutions for processes like spin coating or ink-jet printing to create highly uniform thin films.

- Medical/pharmaceutical applications: Syringe pumps are used in medical infusion for precise drug delivery and patient care and in pharmaceutical R&D for applications like pH control and autosampling during process development.

Key features to consider when choosing an automated syringe pump

Selecting the right syringe pump requires careful consideration of its technical specifications to match the application’s needs.

- Precision control & accuracy: This is paramount. Look for a low coefficient of variation (CV) for accuracy and precision specifications, as this indicates the system’s ability to deliver a dispensed amount close to the target value reliably and repeatedly. For example, the Atlas Syringe Pump offers a typical accuracy of 0.20% CV and precision of 0.06% CV.

- Programmability & automation: The syringe pump should support automated, complex dosing routines, not just simple volume delivery. Features like pH control and integration with other lab equipment and software are crucial for walk-away experiments and safety.

- Flow rate control & range: The flow rate range should span from the minimum necessary for micro-scale reactions up to the maximum throughput required. Consider if the pump can provide smooth, pulseless flow (low ripple) even at low rates, which is often a key differentiator from other pump technologies.

- Syringe compatibility: Ensure the syringe pump can accommodate a range of syringe sizes and materials for different volumes and chemical compatibilities. Wetted parts should be chemically resistant (e.g., glass, PTFE, PCFE) for use with various reagents and solvents.

- Channels & continuous flow: Assess whether a single syringe, dual syringe, or multi-channel configuration is needed, and whether you need a continuous flow syringe pump. For continuous processes, confirm the syringe pump supports robust continuous-flow strategies (dual syringe pump with valves).

- Interfaces & control software: The syringe pump should have appropriate interfaces and software for easy control, data logging of parameters, and integration with other devices.

- Safety: The unit must incorporate safety features to mitigate risks like leaks, spills, and over-pressurization through pressure monitoring protocols

Need help selecting your syringe size? Contact our chemistry specialists, who are more than happy to help.

Maintenance and troubleshooting

Regular maintenance and proper use are essential for ensuring long-term performance and reliability, addressing pain points like common issues and maintenance.

- Cleaning procedures: Due to their construction from chemically resistant materials (glass/PTFE), syringes and wetted parts should be regularly cleaned with appropriate solvents, especially after using corrosive or sticky reagents. Quick-release mechanisms for syringes and valves (like those on Atlas Syringe Pumps) simplify this process.

- Calibration guidelines: While modern syringe pumps are highly stable, periodic checks (calibration) may be necessary to maintain optimal accuracy. Gravimetric dosing studies are a common way to accurately verify performance.

- Common issues and troubleshooting:

- Air bubbles/cavitation: These are major sources of dosing errors. Use the shortest, smallest bore tubing possible. For volatile solvents, using an Asia Syringe Pump Pressurized Input Store to apply a slight inert gas pressure (1-10 bar) on the reagent source can prevent cavitation and improve accuracy, especially at high flow rates.

- Clogging: Prevent particulate matter from entering the syringe pump by using PTFE input filters.

- Syringe/valve replacement: Syringes and valves are user-changeable and designed for quick replacement without special tools. Always configure the new syringe volume in the syringe pump’s settings after replacement to maintain reliable operation.

Automated syringe pumps: cost analysis and comparison

HPLC type pumps can be used in flow chemistry applications. HPLC pumps are typically dual-piston pumps, although single reciprocating piston pumps can be used. The two pistons are out of phase, like continuous syringe pumps; while one pump head fills, the other delivers.

The material of construction can be 316 stainless steel, titanium, Hastelloy C or ceramic. Stainless steel pumps are most common and can have chemical compatibility issues, so you need to be careful with the construction material.

Automated syringe pumps: cost analysis and comparison

The total cost of an automated syringe pump involves both initial purchase price and long-term expenses.

- Factors influencing cost: Initial cost is driven by precision/accuracy specifications (higher precision equals higher cost), flow rate range (larger volumes/faster rates often require larger, more expensive pump drives, number of channels, inclusion of specialized modules (e.g., pH node, autosampler), and level of syringe pump automation/software features.

- Comparison of models and brands: Brands like WPI and Hamilton are recognized, but can sometimes offer limited content depth or detail on specific models. Syrris aims to differentiate by offering a balanced, application-focused guide, clear comparisons, and comprehensive coverage of troubleshooting, exceeding the depth of typical product descriptions.

- Single syringe or dual syringe pump: do you need to dose a certain volume continuously with high precision?

- Long-term cost considerations: Durability (chemical resistance) and ease of maintenance (tool-free parts replacement) lower the long-term cost of your syringe pump. A robust warranty and readily available local support are also crucial cost-saving factors. Purchasing a versatile, modular system like Atlas Syringe Pump or Asia Syringe Pump (for flow chemistry) minimizes future upgrade costs by allowing expansion for new applications (e.g., electrochemistry, photochemistry, automated sampling, etc…).

Contact us

Contact our specialists for help choosing the best syringe pump for your application.

Ask us:

- The correct syringe diameter

- How to choose the best syringe pump for your chemistry

- About syringe pump automation software

- For user manuals and technical specifications

Syringe pump terminology

When selecting your syringe pump, you should be aware of the following terms used by manufacturers when describing their products:

- Flow rate: Volume of fluid delivered per unit of time. Atlas Syringe Pump offers a flow rate of 0.5 μl/min to 20 ml/min standard pump and up to 200 ml/min with Atlas Syringe Pump XL. The Asia Syringe Pump offers a flow rate of 1.0μl to 10ml/min – ideal for continuous flow chemistry

- Force / occlusion pressure – syringe pumps are rated by plunger force/occlusion thresholds. Asia Syringe Pump has a very wide pressure range of Up to 20bar/300psi. A syringe pump should offer pressure monitoring, for example the Asia Syringe Pump has a pressure sensor on each channel to offer real-time pressure monitoring.

- Microfluidics: The study and manipulation of fluids at the microscale.

- Infusion: The process of delivering fluid into a system.

- Withdrawal: The process of drawing fluid into a syringe.

- Stepper motor: A motor that moves in discrete steps, allowing for precise control.

- Laboratory syringe pump: A specialized syringe pump that are used for precise reagent addition, kinetic studies, and reaction optimization where high precision volume or flow rate control is critical for reproducible results. Laboratory syringe pumps often offer automation software and control software for complex dosing regimens.

- Luer lock: A standard connector for syringes and needles.

- Dead volume: Volume of solution that remains in the syringe tubing after dispensing

- Channels: single syringe / dual syringe / multi-channel and continuous-flow strategies (dual syringe + valves) are available.

- Interfaces & control: how a pump is controlled and automated USB/RS-232/485, TTL/Ethernet; software APIs such as LabVIEW or other general interface families are standard in lab control. Syrris Asia and Atlas Syringe Pumps offer control and automation from manual interface on the syringe pump and via Atlas PC Software, Asia Manager PC Software, and OPC UA powered Asia External Control software.

- Pulsation / ripple: the stability of the flow profile. Asia Syringe Pumps offer ultra-low pulsation