Publication – Continuous metal scavenging and coupling to one-pot copper-catalyzed azide-alkyne cycloaddition “click” reaction in flow chemistry

Chemical Engineering Journal, 2015, 468-475

Iris Vural Gürsel, Ferry Aldiansyah, Qi Wang, Timothy Noël*, Volker Hessel

Department of Chemical Engineering and Chemistry, Eindhoven University of Technology, Eindhoven 5600 MB, The Netherlands

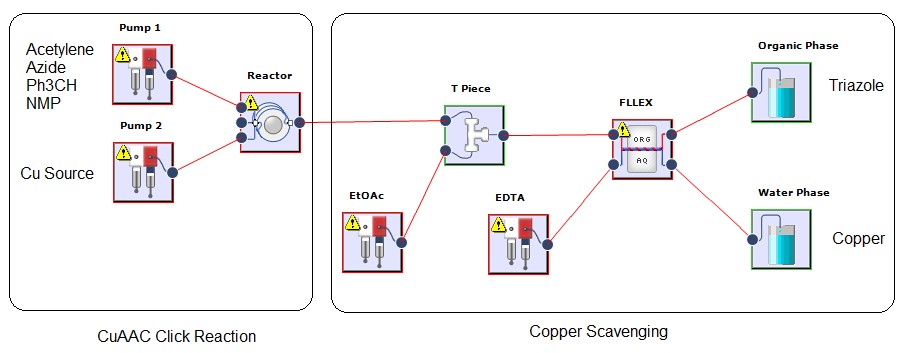

Using the Syrris Asia FLLEX (Flow Liquid Liquid Extraction) module researchers at the Eindhoven University of Technology have demonstrated an efficient extraction method to continuously remove metal catalysts from an azide-alkyne cycloaddition click reaction in flow. The formation of triazoles via azide intermediates have been previously investigated and are a key flow chemistry application as the potentially explosive azide intermediates are generated and consumed immediately. 1,2,3-Triazoles are also key structural motifs in a variety of applications ranging from drug discovery, chemical biology, and material science. Coupling reactions of this type with a downstream work-up demonstrate effective process intensification. The group describes a full evaluation of the FLLEX with model extraction systems before developing continuous copper extraction. The copper scavenging of various copper catalysts was investigated looking at the effects of chelating scavengers (EDTA, DTPA, EDDS), concentration and pH. The formation of the desired triazole product gave excellent yields of 92% with the extraction performance as high as 99%. The copper content of the organic phase was shown to be lower than the level of purity required for the pharmaceutical (APIs) limit of 15 ppm in a single separation step.

Abstract: Increasing usage of catalytic chemistry calls for the efficient removal of metal traces. This paper describes the development and optimization of a scavenger-based extraction in flow to remove metal catalysts. It enables liquid–liquid extraction with slug flow and phase separation with a porous fluoropolymer membrane. The use of this unit for copper scavenging of various copper sources from organic solvent was studied. The effects of scavenger type (EDTA, DTPA, EDDS), concentration and pH were also investigated. Such analysis allowed to achieve extraction performance as high as 99% at pH of the scavenger solution adjusted to 9.4 and molar ratio of scavenger to copper of 10. Process integration is achieved by coupling this unit downstream to a flow reaction using homogeneous metal-based catalysis, i.e. presenting a continuous uninterrupted metal scavenging unit. The copper-catalyzed azide-alkyne cycloaddition click reaction is studied in one-pot eliminating the need to isolate and handle potentially explosive azide. The triazole product is attained in flow with a high yield of up to 92% with 30 min residence time. The level of purity requirement for pharmaceuticals is met in one stage of extraction.

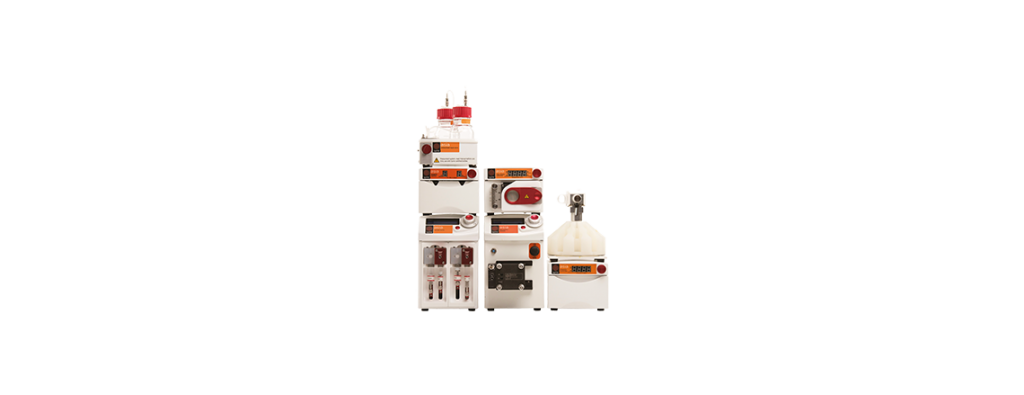

This paper uses an Asia FLLEX Module. Learn more about the module this chemistry was performed on.