Publication – Development of a continuous flow sulfoxide imidation protocol using azide sources under superacidic conditions

Organic Process Research & Development 2015, 19 (8), pp 1062-1067

Bernhard Gutmann, Petteri Elsner, Anne O’Kearney-McMullan, William Goundry, Dominique M. Roberge, and C. Oliver Kappe

Institute of Chemistry, University of Graz, Heinrichstrasse 28, A-8010 Graz, Austria

Microreactor Technology, Lonza AG, CH-3930 Visp, Switzerland

AstraZeneca, Silk Road Business Park, Macclesfield SK10 2NA, United Kingdom

This paper published by Oliver Kappe’s group from the University of Graz, in collaboration with Lonza and AstraZeneca, focuses on an efficient flow protocol for the synthesis of sulfoximine. The imidation of sulfoxides using azides and concentrated sulfuric acid is a high-yielding process for synthesizing sulfoximines but the hazard risks associated with it renders it unsuitable for batch production. It is however perfectly suited for a continuous flow process.

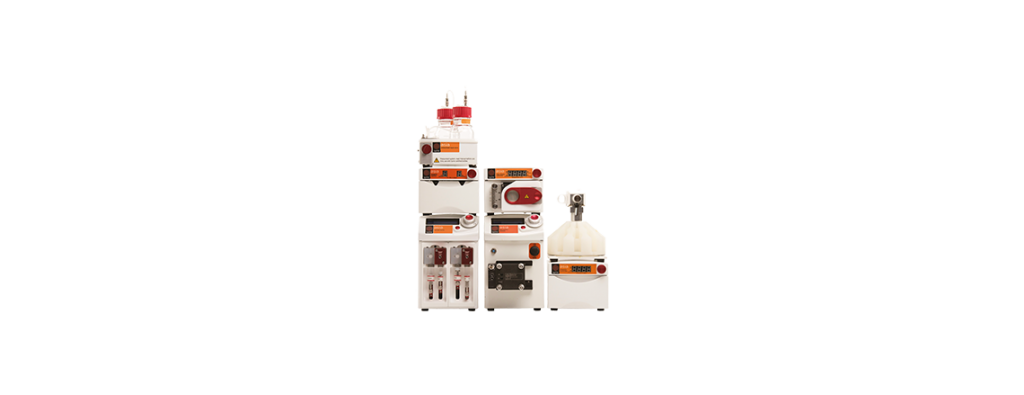

The use of two Asia Pumps allowed Kappe’s group to pump fuming sulfuric acid and dichloromethane into a flow chemistry setup and achieve 95% conversion with >85% selectivity.

Abstract: The development of a continuous flow sulfoxide imidation protocol for a pharmaceutically relevant target molecule is described. Sulfoxide imidation is a key step in the preparation of certain ATR kinase inhibitors. Reactions with NaN3 or TMSN3 and concentrated sulfuric acid under literature conditions provided low conversions and poor selectivities. In contrast, reactions employing fuming sulfuric acid afforded the target sulfoximine with a selectivity of ~90% after a reaction time of only 10?15 min at 50 °C. The imidation reaction using TMSN3 as the reagent was successfully performed in a flow reactor utilizing CH2Cl2/H2SO4 biphasic conditions. The mixture was subsequently quenched in-line with H2O. Phase separation, neutralization, and re-extraction with anTo download the paper click here

This paper uses the Asia Syringe Pumps. Learn more about the product this chemistry was performed on.

For more information, contact us.