Pressure reactors: a comprehensive guide

A pressure reactor is a specialized, sealed vessel designed to safely conduct chemical reactions and processes under high pressure, high temperature, or both. Often called a high-pressure reactor, stirred autoclave, or pressure vessel, this equipment is essential for accessing unique chemical pathways and achieving reaction conditions that are impossible in standard atmospheric glass reactors.

When do you need a high pressure reactor rather than a standard glass reactor

You need a high-pressure reactor whenever your process involves highly volatile liquids, gaseous reactants, or reaction temperatures significantly above the solvent’s boiling point. They differ fundamentally from a standard glass reactor by being fully sealed and constructed from materials capable of withstanding extreme internal working pressure (up to hundreds of bar) and temperature.

What is a pressure reactor?

A pressure reactor or high pressure reactor is a pressure vessel engineered for laboratory or industrial use to contain and control chemical reactions at pressures above atmospheric levels.

Basic components and functionality:

The core functionality of a pressure reactor involves a robust, sealed vessel body and a secure headplate, often fitted with inlets for gas or liquid addition, a thermocouple for temperature control, and a sealed stirring mechanism.

Why use a pressure reactor?

The primary advantage of a pressure reactor is the ability to run reactions under high pressure, which increases the solubility of gases in liquids (essential for hydrogenation and catalytic reactions) and permits reactions to be run at temperatures above the solvent’s atmospheric boiling point. This allows for chemical synthesis that is faster and more selective, opening up the chemical space for materials science and petrochemical processes.

Types of pressure reactors

Which types of pressure reactor exist and how do they differ? Pressure reactors come in various forms, dictated by their application and scale:

- Metal pressure reactors (stirred autoclaves): These are the most common laboratory pressure reactors or high pressure reactors. Constructed from robust alloys like stainless steel (SS316) or specialized Hastelloy and Inconel, they feature advanced seals and agitation mechanisms (often magnetic stirrers or magnetic drive agitation) for efficient mixing under high pressure. They’re widely used for chemical synthesis.

- Glass pressure reactors: These reactors combine the high pressure resistance of a steel headplate with the visibility of a glass reactor vessel. Glass reactors are typically limited to lower pressures (e.g., up to 3 bar) but offer the unique advantage of visual monitoring and easier cleaning.

- Pilot-scale pressure reactors: These are larger versions (10 L to 50 L) used in process development for scale-up of high pressure processes.

- Non-stirred/tube reactors (pressure tubes): These include simple, sealed tube pressure vessels, such as the Fisher-Porter tube, which are used for small-scale high pressure material testing without mechanical agitation.

- Parallel reactors: Systems designed to run multiple independent, sealed pressure reactor cells simultaneously, accelerating screening and optimization studies by exploring several variables at once.

- Microwave synthesizers: Specialized reactors that use microwave energy to rapidly heat reactions in small, sealed high pressure vessels.

Applications of pressure reactors

Pressure reactors open up reaction space, enabling chemical synthesis and processes otherwise inaccessible under ambient conditions.

- Hydrogenation: A common application requiring a pressure reactor. Reactions involving hydrogen gas require high pressure to drive the gas into the liquid phase, accelerating the catalysis and improving yield and selectivity. Consider a gas dosing system for safe and reproducible hydrogenations.

- Polymerization: Used extensively in materials science for polymerisation reactions. High pressure influences monomer reactivity and polymer structure, allowing chemists to synthesize unique materials and achieve specific properties.

- Catalytic reactions: Any catalysis involving gaseous reactants benefits from pressure to increase gas solubility and reaction kinetics.

- Hydrothermal syntheses: These processes perform chemistry in hot, pressurised aqueous media, essential for creating new materials.

- Corrosion testing: Used to subject materials to high pressure and temperature conditions for evaluating their durability in harsh industrial or petrochemical processes.

- Supercriticality studies: Pressure and temperature are combined in a high pressure reactor to reach a supercriticality state, where the fluid exhibits properties of both a gas and a liquid, useful for extractions and novel reaction media.

High pressure continuous flow reactors

One of the key benefits of flow chemistry is that processes can be easily pressurized. This allows reactions to be heated 100-150ºC above their normal boiling point, therefore, creating reaction rates that are 1000 times faster. This process is called superheating.

Asia Flow Chemistry Systems can be pressurized at up to 20 bar/ 300 psi. Specialized flow chemistry microreactors and modules such the Asia Pressure Controller and Asia Pressurized Input Store are designed to further enhance high pressure reactions in continuous flow chemistry.

Design and materials

The design of a pressure reactor or high pressure reactor must balance chemical compatibility, thermal demands, and mechanical strength.

- Material of construction (MOC): The MOC of a pressure reactor is determined by the fluid chemistry. SS316/316L is the minimum standard for its strength and general corrosion resistance. For aggressive acids or high pressure applications, Hastelloy (e.g., C-276 or C-22) is often the required alloy. When a metal pressure reactor is still incompatible, a PTFE liner provides chemical inertness while the external metallic vessel handles the pressure. Choose the correct MOC to reduce or eliminate corrosion of your pressure reactor.

- Pressure and temperature ratings: Pressure reactor vessels are rated by their Design Pressure and Working Pressure. The rating must comply with standards, ensuring the vessel can safely contain the maximum pressure (MAWP) and temperature. In the UK, standards are based upon: the Pressure Safety Regulations 2000 (PSSR)

- Safety factors: The mandatory safety factors applied to wall thickness and design, ensuring the high pressure vessel operates reliably far below its bursting point.

Safety features, protocols and best practices

What safety features and certifications should I look for? Safety in a pressure reactor is non-negotiable and mandated by law in many regions.

- Pressure relief devices: All certified pressure reactor vessels must be protected by either a PRV (pressure relief valve), which automatically reseats after a temporary overpressure event, or a single-use rupture disc. The device must meet international standards (ISO 4126).

- Certifications and examination: Look for PED/UKCA conformity markings. Users in the UK must adhere to the Pressure Safety Regulations 2000 (PSSR) and ensure the pressure reactor vessel has a Written Scheme of Examination (WSE) for periodic inspection.

- Best practices and handling: Never exceed the maximum rated working pressure and temperature of a pressure reactor. Implement proper shutdown procedures, and conduct a detailed risk assessment before operating. Implement proper safety measures provided by the manufacturer to prevent explosions.

Pressure reactor accessories and automation

What accessories matter for your pressure reactor configuration, from magnetic stirrer, baffles, sampling valves, liners, data logging, and more.

- Agitation: magnetic stirrer (mag-drive) is the standard, providing reliable, leak-free stirring under pressure by eliminating dynamic seals. The pressure reactor vessel often requires baffles to break the fluid’s rotation and ensure thorough mixing. Magnetic stirrer heads and magnetic stirrer drives can be used for glass apparatus under vacuum or low pressure and for high-pressure reactors on a laboratory and pilot plant scale.

- Monitoring and sampling: Accessories should include specialized high pressure valves fittings for safe charging/venting, pressure gauges, and reliable temperature probes. Sampling valves allow for safe, small-volume extraction under high pressure to track reaction progress.

- Automation and control: Advanced pressure reactors integrate automated control systems for precise regulation of pressure and temperature. Automated dosing systems (e.g., gas dosing) are essential for safe and reproducible H_2 reactions. Data logging via dedicated software is necessary for documenting kinetics and safety data.

Manufacturers and suppliers

Choosing a reputable supplier is as critical as choosing the reactor itself.

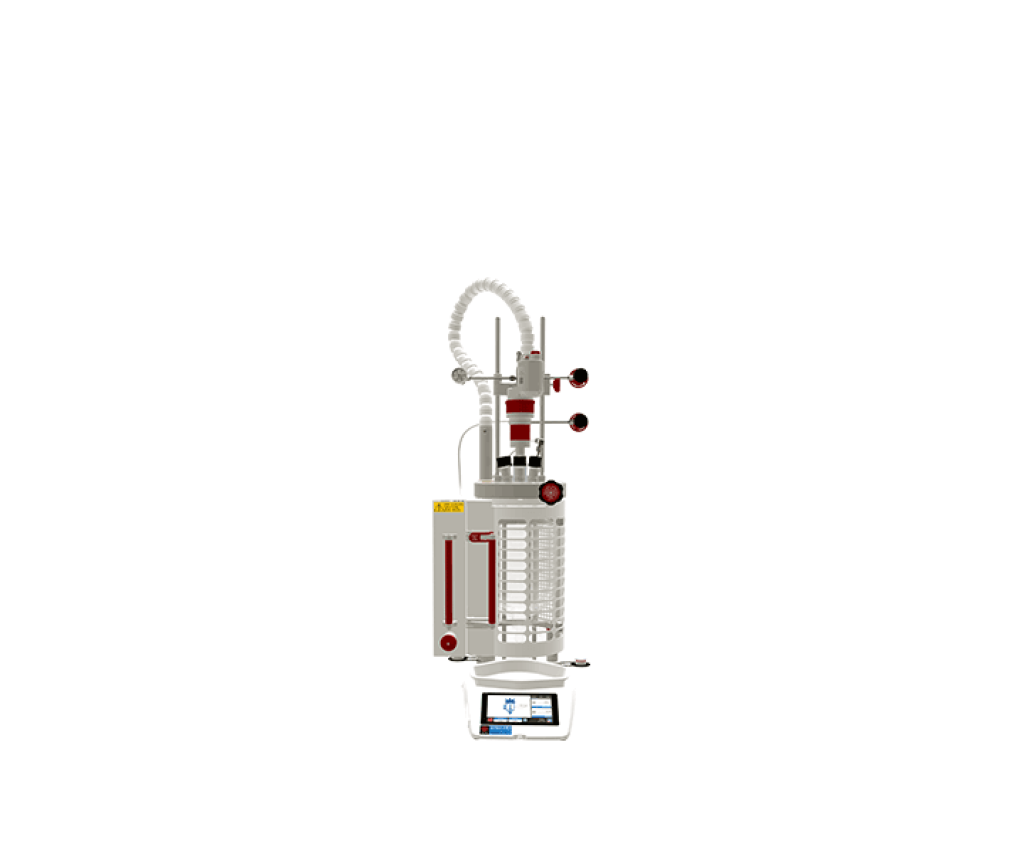

- Syrris: Provides automated laboratory-scale glass reactor systems, including the Atlas HD Automated Jacketed Reactor range which includes the Atlas HD 3 Bar Pressure System, a modular laboratory pressure reactor that can be controlled automatically or manually.

- Premex: Designs and manufactures high quality steel pressure and high pressure reactors in the field of research and development as well as for industrial production. Premex also manufacture magnetic stirrers for lab pressure reactors and pilot pressure reactors.

- Parr Instrument Company: Known for a strong reputation and broad selection, particularly in stirred metal autoclaves and high pressure reactors.

- High Pressure Equipment Company: Specializes in high pressure components and reactors.

- Buchi and MEettler Toledo: Offer sophisticated jacketed reactor platforms with high pressure capabilities and integrated automation systems.

Contact Syrris to discuss your options for a customized pressure reactor.

How to choose your pressure reactor

The following steps offer a brief guide to choosing the correct pressure reactor for your chemistry process:

- Choose the correct MOC (material of construction) of your pressure reactor to reduce or eliminate corrosion. Do you need glass reactor vessels or metal reactor vessels?

- Implement proper pressure reactor safety measures provided by the manufacturer to prevent explosions.

- Consider a gas dosing system for safe and reproducible hydrogenations.

- Consider accessories such as a magnetic stirrer or mag drive.

- Contact Syrris chemistry specialists for customized pressure reactor solutions.

Contact us

Contact our specialists for help choosing the best syringe pump for your application.

Ask us:

- The best material for your pressure reactor

- What accessories you need

- About pressure reactor control and automation software

- For user manuals and technical specifications

Pressure Reactor terminology

When selecting your pressure reactor or high pressure reactor, you should be aware of the following terms used by manufacturers when describing their products.

-

Pressure reactor key terms

- Working pressure: working pressure refers to the normal operating pressure inside a pressure vessel.

- Bar: The bar is a metric unit of pressure defined as 100,000 Pa (100 kPa), though not part of the International System of Units (SI). A pressure of 1 bar is slightly less than the current average atmospheric pressure on Earth at sea level (approximately 1.013 bar).

- Magnetic stirrer: A device used to mix liquids by creating a rotating magnetic field that spins a magnetic stir bar within the pressure reactor vessel.

- Pressure vessel: the term pressure vessels describes a container designed to hold gases, liquids, or vapors at a pressure substantially different from the ambient pressure. For example a glass pressure vessel or metal pressure vessel.

- Pressure relief valve (PRV): a safety device that automatically opens to release excess pressure from a system, preventing damage or failure.