Understanding the calorimetry system: a complete guide

Calorimetry is the science of measuring heat transfer during chemical reactions or physical changes. A calorimetry system is the specialized equipment and software used to quantify the amount of thermal energy involved, giving us crucial data about a system’s enthalpy. This comprehensive guide is designed to provide you with a detailed, technical understanding of calorimetry, its systems, and its diverse applications.

What is calorimetry?

Calorimetry is defined as the process of measuring the heat capacity, specific heat, or the heat absorbed or released during a chemical or physical change. This science is founded on the basic principles of heat measurement and energy transfer, mainly the conservation of energy. Heat measurement is typically performed within a specialized instrument called a calorimeter, which attempts to approximate an adiabatic or isothermal process.

The fundamental principle states that the heat flow gained by the calorimeter or solution must be equal in magnitude but opposite in sign to the heat flow lost by the process of interest. This technique is essential for determining enthalpy change in isobaric (constant pressure) processes and internal energy change in isochoric (constant volume) processes.

Importance of heat measurement in science and industry

Calorimetry provides essential thermodynamic data for everything from fundamental research to industrial process development. It’s crucial for characterizing drug binding, ensuring process safety (by quantifying the risk of exothermic reaction), and optimizing reaction conditions, as calorimetry is used to measure the heat produced during these processes.

Types of calorimetry systems

A laboratory calorimetry system or reaction calorimeter typically consists of the containment vessel, high-precision sensors (for temperature, pressure, etc.), an energy source for calibration, and sophisticated reaction calorimetry software for data acquisition and analysis. Calorimeters are generally categorized by the way they interact with heat transfer.

Categorization by heat flow and temperature control

Reaction calorimeters classified by their principal of operation, key measurements, and common uses.

| Calorimeter Type | Principle of Operation | Key Measurement | Common Use |

| Adiabatic | Designed to prevent any heat exchange with surroundings | Measures the resulting temperature rise of the system. | High-risk, rapid exothermic reactions (e.g., decomposition, runaway reactions). |

| Isoperibol | Measures heat transfer between the reaction vessel and a constant temperature jacket. | Quantifies the of the reaction, with a correction applied for heat loss. | General purpose heat of solution or reaction calorimetry. |

| Isothermal | Maintains a constant temperature by continuously removing or adding thermal energy. | Measures the power required to maintain “T” . | General purpose heat of solution or reaction calorimetry – see Atlas Cal High-sensitivity measurements, like drug-ligand binding studies (Isothermal Titration Calorimeters, ITC). |

Specific calorimeter types

Bomb calorimeter (Isochoric): A sturdy, closed, insulated steel vessel designed for isochoric (constant volume) measurements.

-

-

- Principle: A bomb calorimeter measures the heat released by combustion or explosives. The change in internal energy (“∆ℇ” ) is measured, which is nearly equal to “∆H” for condensed phases.

- Advantage: A bomb calorimetry is accurate for combustion reactions as the constant volume minimizes heat loss and allows the study of high-risk processes.

-

Reaction Calorimeter (Isobaric): Often a sophisticated benchtop reactor system used to track the thermal energy generated or consumed during a chemical reaction in real-time.

-

-

- Principle: Operates typically in Heat Flow (HFC) or Power Compensation (PCC) modes. It directly determines the heat of reaction (“∆H” ) and reaction kinetics.

- Use: Crucial in process development to calculate scale-up parameters and ensure process safety. – Alex add Atlas

-

Differential Scanning Calorimeter (DSC): Measures the heat flow difference required to keep a sample and a reference at the same temperature, while undergoing a controlled temperature program.

-

-

- Use: Ideal for studying phase changes (melting, crystallization), glass transition, and the stability of polymers or pharmaceuticals.

-

Isothermal Titration Calorimeter (ITC): Used for binding studies in biochemistry.

-

-

- Principle: Measures the minuscule heat (enthalpy) released or absorbed when two molecules bind in solution.

- Output: Directly provides “∆H” Gibbs free energy (“∆G” ), and stoichiometry (n) of the binding event.

-

Calvet-Type Calorimeters: A type of heat flux calorimeter often known for high baseline stability and the ability to measure extremely slow processes over long periods.

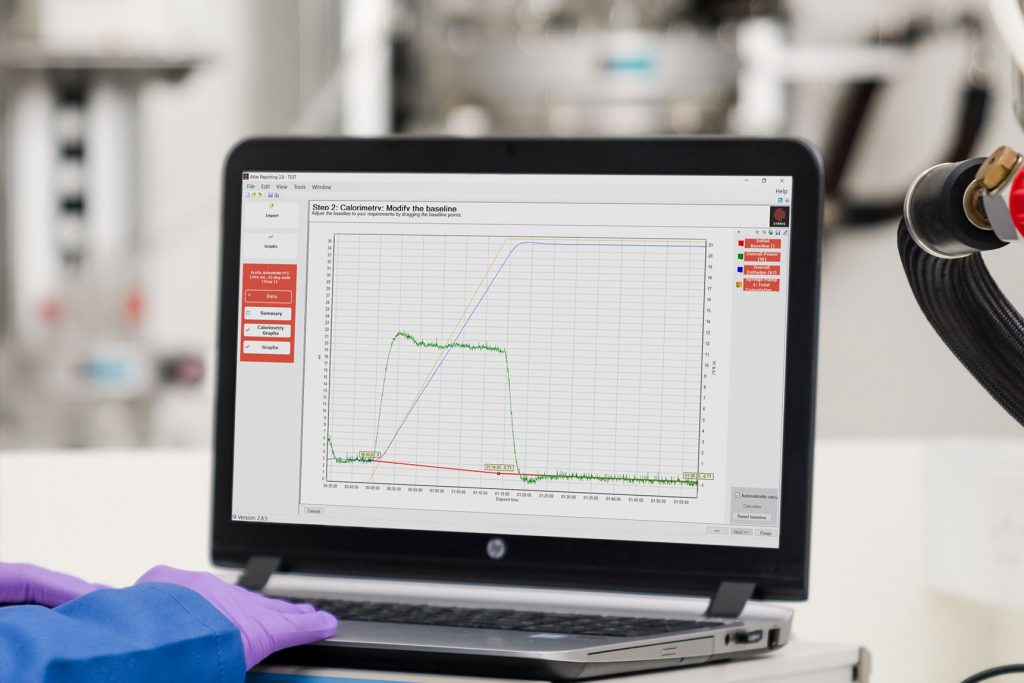

Syrris offer the Atlas HD Reaction Calorimeter, an easy-to-use, high-performance reaction calorimetry system. Using both Heat Flow Calorimetry (HFC) and Power Compensation Calorimetry (PCC), it can generate power and enthalpy graphs quickly and easily.

Heat transfer principles in calorimetry

Accurate reaction calorimetry relies on precisely controlling and quantifying heat transfer. Heat moves through three primary mechanisms:

- Conduction: Transfer of thermal energy through direct contact (e.g., from the reaction fluid to the vessel wall).

- Convection: Heat transfer through the movement of fluids (e.g., stirring of the reaction mass or flow of the jacket fluid).

- Radiation: Transfer of heat via electromagnetic waves (less significant in most lab-scale calorimetry systems).

The rate of heat flow between the reacting mass and the surrounding jacket is a critical parameter. This heat flow is mathematically defined by the relationship involving the Overall Heat Transfer Coefficient:

Q = U A (Tr – Tj)

Where: Q is the rate of heat transfer [W];U is overall heat transfer coefficient [W (m2 K)-1]; A is heat transfer area [m2]; Tr is process temperature; Tj is reactor jacket temperature.

The combined term, UA, represents the overall heat transfer between the reaction mass and the jacket fluid.

U A= Q /(Tr – Tj)

The value of U (Overall Heat Transfer Coefficient) is complex, depending on the material, fluid dynamics (stirring), and viscosity changes. It’s typically calculated from a series of internal and external film coefficients using the reciprocal sum rule, but in reaction calorimetry, the lump sum UA is often empirically determined using internal electrical calibration pulses. Monitoring the UA is critical because changes in reaction properties like viscosity or density will alter it, necessitating corrections in the calculations.

Enthalpy change and heat of reaction: For an isobaric process, the heat of reaction is equal to the change in enthalpy (“∆H” ).

Applications of calorimetry systems

A calorimetry system is a versatile tool across chemical research and industry.

- Process development and safety: This is where reaction calorimetry fits best. It directly helps optimize chemical processes by quantifying exothermic and endothermic reactions. Knowing the heat of reaction is vital for calculating cooling requirements and identifying safe operating limits before scaling up.

- Chemical reactions and synthesis: Calorimetry is used to determine the thermal properties of any new or established chemical reaction. This includes classic demonstrations like combustion reactions (such as in bomb calorimeter) and neutralization reactions.

- Phase changes and materials science: Differential Scanning Calorimeters (DSC) are the go-to tool for measuring the energy released or absorbed during phase changes (melting, boiling, solid-state transitions). This data is crucial in polymer science and materials characterization.

- Binding studies and biochemistry: Isothermal Titration Calorimeters (ITC) are highly specialized for measuring the energy of molecular interactions, such as protein-ligand binding. This data provides the full thermodynamic profile (enthalpy, entropy, affinity) necessary for drug design.

- Metabolic measurements: Room calorimeters are the most accurate way to perform metabolic measurements by measuring the entire heat output of a living organism, often in conjunction with gas exchange.

- Industrial applications: Companies use advanced calorimetry for battery research and characterizing energy storage systems. Modular reaction calorimeters are also sold to enable essential process safety data to be generated more accessibly.

Download the Low Temperature Power PCC Study to see the accuracy of the Syrris Atlas HD Calorimetry system with respect to low temperature calorimetry applications.

Calorimeter calibration

Calibration is a fundamental step for obtaining accurate, verifiable information from any calorimetry system.

Electrical calibration – used in Heat Flow Calibration: This is the most common technique. A known amount of electrical thermal energy is deliberately introduced into the system via a heater, simulating a known heat release. By observing the temperature response, the system’s ability to measure heat is validated. This is often performed pre- and post-reaction. This is used to precisely determine the UA value (overall heat transfer coefficient) of the vessel, crucial for accounting for subtle heat transfer changes due to mixing or viscosity variation.

Chemical Calibration: Running a well-established reaction with a known enthalpy change (e.g., standard neutralization reactions) to verify the calorimeter’s thermal inertia and mixing efficiency.

Calorimetry terminology

When selecting your calorimetry reactor, you should be aware of the following terms used by manufacturers when describing their products:

- Constant pressure heat capacity (Cp): Amount of heat required to raise the temperature of a substance by 1 degree Celsius at constant pressure.

- Constant volume heat capacity (Cv): Amount of heat required to raise the temperature of a substance by 1 degree Celsius at constant volume

- Enthalpy (H): Thermodynamic property that is the sum of the internal energy and the product of pressure and volume.

- Exothermic: Process that releases heat to the surroundings (Q<0).

- Endothermic: Process that absorbs heat from the surroundings (Q>0).

- Adiabatic: Process with no heat exchange with the surroundings (Q=0).

- Isothermal: Process occurring at a constant temperature.

- Isobaric: Process occurring at constant pressure.

- Isochoric: Process occurring at constant volume.

- U (overall heat transfer coefficient): The amount of heat that passes through a specific amount of material for every degree (Kelvin) temperature difference.

- UA: Represents the overall heat transfer between reaction mass and the jacket fluid. Used to account for viscosity changes.

Contact us

Ready to explore related topics and delve deeper into specific calorimetry system applications? Contact Syrris today so we can help you choose the platform for your process.